How do you know for certain that you’re growing your painting company the right way? It’s a tough question to answer. It requires you to look at every aspect of your business. From bidding to your punch list process and everything in between, it all affects the financial health of your business. Job costing is the key to answering this question and almost every other question about your business.

Consistent job costing is crucial for profitability and long-term success, as it allows for fair pricing strategies, efficient project management, and informed decision-making. As an owner/operator of a painting business, you have tremendous potential to grow a trade that will always be in demand.

In this guide, we’ll breakdown all the essential job costing tips for painting contractors so you can job cost consistently and effectively.

Painting industry at a glance

The painting industry (construction and maintenance) is projected to show little to no growth in employment from 2022 to 2032.

Painting industry overview (as of 2023):

- National average take-home pay for painters: $46,090 per year ($22.16/hr)

- Active painting contractors in construction and maintenance: 215,680

- The average size of painting business: 1.5 people

In this environment, ensuring you’re getting the most out of every job has never been more important. Efficiency and productivity are paramount for your business to thrive.

What is job costing?

Essentially, job costing is the tracking of all major job costs for an individual job. These major job costs are as follows:

- Labor

- Materials

- Equipment

- Subcontractor fees

- Misc costs

To job cost, you’ll allocate costs for each category and track actual spending for each category throughout the job. At the end of the job, you’ll see exactly how much you spent in each cost category.

This information lets you precisely compare actual painting costs to your collected revenue. From there, you can see where you made your money, how you made your money, where you came up short, and why it impacted profitability.

Why painting contractors should care about job costing

You’re just as much of a business owner as you are a painter

What separates the most financially successful painting contractors from contractors who struggle week to week? It’s not skill or painting ability and it certainly isn’t luck. It’s not even market factors (we know how much you want to blame Sherwin-Williams).

The differentiator is business acumen and strong accounting principles, (i.e., job costing). Job costing has the potential to dramatically improve the financial standing of your business. Not because it provides some sort of silver bullet or get-rich-quick scheme. In fact, it’s the opposite.

Job costing forces you to face the reality and inner workings of your business. It reveals your triumphs and exposes exactly where your business needs to improve. It unlocks the secrets to all the challenges and uncertainties your business may face. It’s the ultimate tool for understanding and addressing the unique needs of your business.

Job costing is critical for solving common business problems

- Am I actually making money?

- Am I estimating the correct price?

- Scheduling correctly (how do you schedule?)

Data-driven decision-making

If you have months worth of jobs booked out, a good stream of money coming in, and you’re increasing your take-home pay, you’re completely fair in thinking your business is set up for success.

But what does your data say? Can you prove that you’re actually making a profit? Can you prove that you’re set up for long-term success, or does it just feel like your business is prosperous? Remember that feelings are deceitful; data is truth.

All those feelings could be right, but you could still be operating at a loss, especially if hiring new employees or taking on more jobs. On that same note, job costing takes on even more importance if you’re trying to expand your business because it’s the only way to have a real-time look into your profitability. It removes any feelings-based decision-making and replaces it with data-driven decision-making that allows you to grow your business the right way.

In the next section, we’ll break down how it’s the best way to measure job performance and the insights it can reveal to make your next job–and every job–more profitable.

Measuring job success

To understand if you’re growing your business the right way, you need to measure the success of each individual job. The way to do that lies with Gross Profit, which ultimately reveals how much you made after paying for direct costs.

Knowing how much you have in gross profit is essential because it impacts your ability to spend everywhere else since it represents money that is actually yours to spend. For this reason, improving your job level gross profit as much as possible should be a recurring goal.

How to calculate Gross Profit:

- Gross Profit = 100% – (Labor % + Material %)

- Gross profit margin = Gross profit / Total revenue

For example, take your revenue for the job (represented as 100%). Then subtract 40% (labor), then take out another 15% (materials), leaving 45% of money left over that you can actually use to run your business–this money left over is gross profit.

From there, you can take this leftover money and remove any fixed costs (overhead costs, owners pay, salaried employees, etc.), and any money left over after that is known as Net Profit. The kicker here is that owner’s pay (or what you pay yourself) must be subtracted from revenue to accurately represent Net Profit.

You’re missing a huge piece of the puzzle if you include your owner’s pay in net profit. It’ll skew your numbers in a significant way. Of course, all of this depends on the size and nature of your business and the complexity of the jobs you take. It’s okay if your percentages are slightly different than what we’ve showcased here. With that said, you should strive for the following benchmarks.

40%+ is what you should be aiming for. If you notice your gross profit coming in below that you must look into the reason why. Here’s how to do that:

Step 1: Check consistency of jobs

- Ensure your jobs consistently reflect a gross profit at or above 40%.

- Anything above 45% indicates a financially stable business operation.

Step 2: Determine reason for low gross profit

- If your gross profit is below your target of 45% (let’s say your every job from the past few weeks is coming it at 30% or lower) you must look into the underlying reason.

- This will help you identify the issue and find opportunities for improvements to avoid potential losses.

For example, if you complete a residential interior painting job for $3,000 let’s assume you tracked the following numbers:

- You spent $1,000 on labor and $800 on materials.

- This means that your total direct costs (job costs) for this job are $1,800 ($1,000 + $800).

- The remaining revenue after direct costs is $1,200 ($3,000 – $1,800).

Step 3: Calculate gross profit

- To determine the gross profit, divide the remaining revenue of $1,200 by the initial job cost of $3,000.

- Your gross profit for this job is 40% ($1,200 / $3,000).

- While 40% is admirable, it’s still below your target of 45%, indicating you have room for improvement.

Step 4: Identify areas for improvement

- Review your cost data carefully. Search each of the main cost categories and evaluate how it tracked against your budget. If you overspent in any or multiple categories, use that as a starting point for digging in deeper.

- In order to reach your target profit margin, consider raising prices, estimating more accurately, and controlling job and material costs more effectively.

- More than likely, you’ll need to implement all of these strategies to reach your target goal. However, you should always back your decision with what you’re seeing in your job costing numbers. Let the data help you identify which strategy is right for your business.

Step 5: Set a reasonable target and stick to it

- Set a gross profit goal of 40-50% and review every job to see how close your getting to that goal. Never overlook a job no matter how successful or unsuccessful it was. Treat each job as it’s own entity.

- Review every job every week to help you maintain a financially stable operation with maximized profits.

How to get started

To get started with job costing, you must understand each main cost category. You’ll need to track, evaluate, and report these cost categories to gain the valuable data that job costing can give you.

Each job will have its own circumstances impacting how you allocate each cost, but generally, jobs within the painting industry will focus largely on labor first and materials second. It’s also important to note that job costing does not take into account overhead.

Understanding the major cost categories

Labor costs

Labor will likely be your biggest expense (as a percentage of revenue) for every job–usually accounting for 80-85% of total costs. Since labor accounts for such a large portion of job costs, optimizing labor is one of the biggest things you can do to turn your business around. It’s your biggest opportunity to cut costs and improve profit margins.

Labor will boil down to your physical efforts (if you’re an owner/operator) or the painting services performed by your employees. On that note, whether you have a crew of painters or not, you should track your own labor on every job. If you’re the sole painter in your business, tracking your labor is essential since you account for all the labor costs.

But if you have a crew of painters and you step in to help with a part or all of a job, you still need to account for your labor costs. Your employees don’t work for free, and neither should you. Any labor spent on a job means time, money, and resources are spent to complete the job. Don’t miss out on capturing these costs.

If you’re not sure what your wage should be as company owner, there are a few steps you can take. First, consider your financial goals, desired salary, and any business needs specific to your company. Second, contact your accountant and have them help you work through an appropriate rate that will accurately factor in the above considerations.

To calculate labor costs, you’ll need to answer the following questions:

- Who did the job?

- What is their wage?

- How many hours did they take to complete the job?

However, there’s still a huge missing piece of the puzzle. When you employ and schedule a painter on a job, the cost they incur on your business is far beyond their hourly wage. The total cost they incur on your business includes taxes, insurance, bonuses, or any paid time off you offer.

These costs comprise that missing piece of the puzzle, known as labor burden. We can’t stress enough how important labor burden is. Missing labor burden will put you out of business. This is especially true in the painting trades, where labor is such a significant cost.

Labor burden includes:

- Payroll taxes

- FICA

- Medicare

- Social security

- Health insurance

- Dental

- Vision

- Workers comp/liability insurance

- Retirement contribution

- Bonuses

- PTO/Vacation

You must also account for seemingly small everyday costs such as:

- Company cell phones (or other communication expenses)

- Insurance for any equipment used by an employee

- Training and employee development

- Company apparel

To calculate labor burden, gather payroll reports for information such as hourly wages, taxes, unemployment insurance, and fees from your payroll provider. Also, be sure to track down workers’ comp and health insurance costs.

Use the following formula to calculate a labor burden percentage for each employee:

(Burdened labor costs + Additional costs) / Wage * 100%

In addition, convert annual numbers into hourly rates by dividing by 2080 (working hours in a year). For a more accurate approach, take a look at our full breakdown of labor burden to learn everything you need to know about labor burden in construction.

Material costs

Paint will, of course, be a huge cost at play here. But just as labor costing isn’t as simple as just marking down hourly wages, material costs are more complex than just writing down retail prices for coats of paint.

For example, if you go out and buy a can of paint for $59.99, it’s easy to track that job cost down as $59.99. However, this is leaving out an entire ecosystem of costs attached to that can of paint. These include sales tax and paint disposal tax that applies to select states. All associated costs must be allocated to every gallon of paint you use.

How granular do you have to be? Should you track every little piece of tape, patch, or brush that you buy? You certainly can if you have the resources and will to do so. However, this can quickly spiral out of control.

While we do recommend getting as specific as possible with your material costing, for smaller purchases though (i.e., brushes and rollers, tape, patch, pans, and plastic), you should track how much you’re spending on these purchases over the course of 3-6 months, or better yet, an entire year. Then, average out these purchases into a percentage that is spread across all jobs.

For example, suppose you’ve collected $500,000 in revenue over the course of a year and you spent $5,000 on sundries during the same year. In that case, you can confidently arrive at an average percentage (1%) that you can use to allocate to all future jobs. In other words, add 1% to your budget to account for small purchases.

When tracking paint costs, breaking it down by gallons of paint and then cost per gallon is a solid way to set yourself up for accurate tracking. You can also use a more standardized pricing method, such as per square foot or unit pricing.

Painters fixate on materials because you can clearly see the numbers on the shelf. Seeing these costs is unavoidable. However, material costs should be around 15% or less of total job costs.

Equipment

If a paint job calls for specialized tools or equipment such as power washers, scaffolding, or lifts, you’ll want to make sure the costs of renting, owning, or operating this equipment are captured in your job costing reports.

Ownership costs include depreciation, insurance, and licenses, while operational costs include fuel and repair expenses. In addition, leasing costs cover any leased equipment used.

Subcontractor fees

Take into consideration any fees associated with additional subcontractors needed for the job. For example, you may need another team to work drywall or electrical. Put together a clear subcontractor agreement outlining the scope of work and price. By bringing in extra subcontractors, you can save money and focus on your main strengths.

This will help you avoid taking on tasks beyond your capabilities. However, it’s important to carefully evaluate if their services are necessary to meet the project deadline. If so, carefully review bids and include these costs in your budget planning.

Miscellaneous costs

These additional costs, such as indirect costs, are not included in labor, materials, equipment, and subcontractor fees. Although they may not have as much financial impact as direct costs (i.e., labor and materials), they’re equally crucial to factor into your cost breakdown. If left unchecked, these costs can quickly accumulate and jeopardize the profitability of a job.

Miscellaneous costs:

- Permits

- Bonds

- Insurance

- Financing fees (loans/interest)

- Contingency funds

Start with a budget

Ideally, you’ll start every project with a budget that you can use to track each category to see how actual costs compare to your estimate.

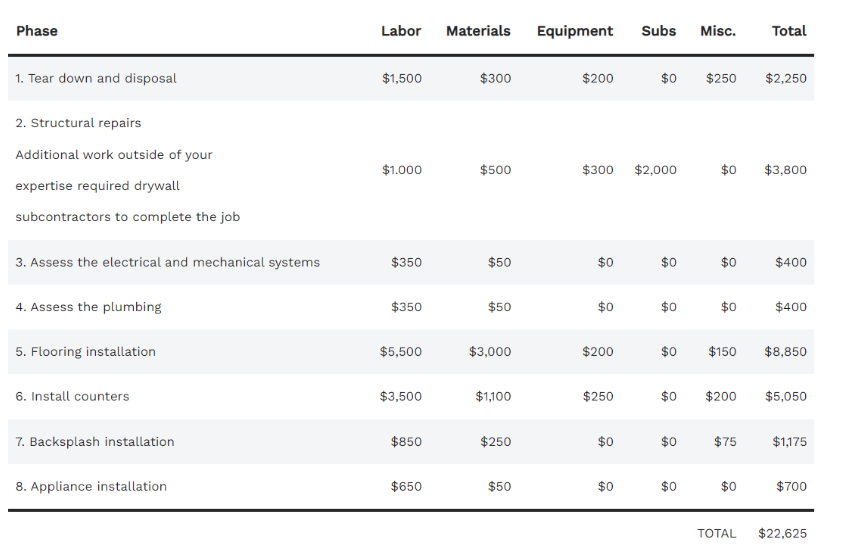

To do this, you’ll need to create a line item-by-line item budget for labor cost, materials, equipment, subcontractor costs (if applicable), and any additional costs that fall outside those categories. Considering these major cost categories, break the job into phases. It’ll look something like this:

Don’t provide a general lump sum for each phase. Break down each phase into the major cost categories. This will give you an accurate way to estimate a painting job from the get go.

For instance, rather than estimating a blanket $22,625 for the entire job, determine the individual costs for labor, materials, equipment, subcontractor fees, and miscellaneous expenses that will go into each phase.

You can use our free construction budget template to help you get started on a budget that will keep you on-schedule and under budget.

How to evaluate the data

Capturing all of this data wouldn’t be worth the effort unless you regularly evaluate it. Consistency matters here. If you job cost once a year or once a month, you’re missing the point; try to job cost every job and review the data from every job every week.

What to look for:

- Trends in cost overruns

- Under or overspending

- How well did you do against your budget?

- Did you leave money on the table?

- Did you schedule correctly?

- How accurate was your estimate compared to actual spending?

- If you didn’t make money, was it an efficiency problem or a pricing problem?

Look for trends on both an individual job level and over the course of several jobs. The goal here is to see how your previous budget performed. Did you meet your budget, or did you go over? It can be difficult to revisit and learn from mistakes that resulted in overspending, but it’s crucial for improvement and identifying recurring errors.

Essential job costing tips for painting subcontractors

- Always account for labor burden

- Break the job down into phases with a budget for each phase

- Use past estimates to narrow down on accurate paint costs

- Visit the job site to personally evaluate any potential issues or nuances of the job

- Create an emergency fund: 3% of all revenue should be withheld and saved in cash in a business account for an emergency fund or two months of operating expenses, just in case. Back this up with a line of credit.

Problem-solving with job costing

No matter what trends or numbers you see, you should always strive to improve efficiency (get the job done in less time with less waste), standardize your processes, and renegotiate with suppliers for better prices and terms.

Running a painting business is not a pass/fail endeavor. For example, say you just opened a painting business as a single owner/operator. After a full year, you generate $100,000 in take-home pay.

This is an admirable achievement for sure. However, you had to work 100-hour weeks in order to achieve this. When you break the numbers down, you’ll see that you only made $20 per hour ($100,000 / 5000hr = $20/hr). $20/hr is less than the industry average of $22.16/hr. While the $100k is great, it’s clear that you’re wasting valuable time and leaving money on the table through an inefficient business operation.

Had you job costed this entire time, you’d have quickly realized the plethora of adjustments and alterations you could’ve made to improve efficiency, enhance profitability, and, most importantly, save time.

If you have to work 100 weeks to achieve your financial goals, you’re operating at an unsustainable level. Instead, aim for something closer to $60/hr at 40hr weeks. This is a much healthier and more sustainable business operation. Job costing will reveal the truth of your business and will be the only reliable way of assessing your true profitability.

We’ll now look at some common questions painting contractors frequently ask themselves and how job costing can help solve those issues.

Am I actually making money?

If you’re noticing that you’re not generating the profitability that you expect, the inclination is to jump to materials. However, it’s not Sherwin-Williams’ fault you’re not making any money. It’s likely due to your own inefficiency and lack of accurate labor costing.

Labor is likely the source of your profitability woes, but with that said, there are steps you can take to ensure materials are not dragging your profits down. This begins with negotiating with your vendors. Try to seek out two or three suppliers that you can reliably deal with and see if you can get better terms for your business needs.

Then, look into your estimating process. You should consider revamping your estimating process if you’re consistently off the mark in your material spending. It likely means you’re not allocating enough costs to materials for this type of job (more on this in the next section).

Another common inclination is to raise prices. However, job costing will tell you if your profitability issues are caused by low prices or from within. A major benefit of job costing is its ability to force to look inwards first and foremost. Better labor costs are paved through a more efficient workforce and a better product. This only happens by identifying painting cost overruns and making corrections to reel in costs.

Now, this doesn’t mean you shouldn’t raise your prices at all. If you can justify a price increase, then by all means, but don’t rely on price increases as a fix-all. It may help revenue figures in the short term, but if your gross profit numbers are still chronically low, you’ll eventually run into the same issue.

Industry benchmarks:

- Gross Profit: 45%+

- Labor: 40%

- Material: 15%

You need to start looking inward and improve labor efficiency first and foremost. Looking back at the industry benchmarks, you should consistently review every job’s labor costs as a percentage of revenue. If it’s consistently higher than 40%, you and your painters need to paint more efficiently, with less waste, and to a standardized process.

Am I estimating the correct price?

What should I charge for fill-in-the-blank? It’s a common question, but as we’ll learn, job costing can help you zero in on what to charge for a certain type of project or task within a job.

To start this assessment, take a look at your backlog. The sweet spot for effective pricing will have you booked out 1-3 months in advance. If you’re struggling to book out jobs, then a price evaluation is definitely needed. However, you should reevaluate your pricing strategy if you’re booked out six months or even a year in advance. This is because you may be underselling yourself.

There are exceptions to this, but a year in advance likely indicates that your prices may be drastically too low for long-term sustainability. This is basic supply and demand at work. If there’s a large supply of a cheap service, people will take a lot of it. This is good for customers but not so great for running a financially stable painting business.

In short, if you look at your numbers and your crew finished a paint job under the allotted time, and you came in under budget on materials, and you still missed your gross profit goals, then you have a very logical case for increasing your prices.

Scheduling correctly (how do you schedule?)

Scheduling is an interesting element of business management that job costing can elevate. This starts with budgets, of all unlikely things. Give yourself or your workers a clearly defined goal at the start of the project. These goals help give something to strive for, which is a nifty way of keeping the project driving forward.

- Project budget = ( Revenue – Estimate materials) / Rev/hr goal)

- Example

($2000 – $200) / $70 = Project budget

($1800) / $70 = 26 hours to complete the job (if you keep material costs to 15%)

You can extrapolate this information to help you plan out jobs and decide how and who should tackle what.

When scheduling and determining how many hours a paint job is likely to take, you should factor in job site prep, drive time, lunch, and things like clean-up time. Any time spent on the job site in service to the job should be allocated to that job.

This, of course, depends on your preferences, whether or not you want to pay for lunch, but when in doubt, if time is spent in service of the job, it should be allocated to that job.

Build your business with confidence

Every minute spent on tedious administrative tasks is a minute away from doing what you love. Whether you need to improve how you estimate painting jobs, need to improve profitability or want a more efficient business, Knowify’s integration with QuickBooks Online (QBO) is a true gamechanger.

By seamlessly connecting bookkeeping with job level management, Knowify eliminates the need for duplicate data entry. No more typing the same information into both platforms, wasting precious time and increasing the risk of error.

Buy a subscription to QuickBooks Online with your Knowify subscription and get the lowest combined price available anywhere, guaranteed. Schedule a demo to find out more.

Build your business with confidence with organized projects that stay on-budget

Meet a Knowify expert on a video screenshare, get your questions answered, and ensure you’re set up for organized, profitable projects with Knowify.